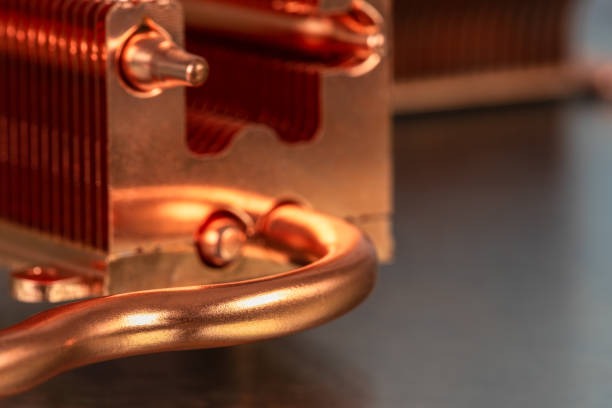

Achieving maximum heat transfer in electronic devices is a critical challenge faced by engineers and designers, especially as the demand for more powerful and compact technology continues to grow. One innovative solution that has emerged to address this challenge is the use of tungsten copper heat sink alloys. These materials offer a unique combination of properties that make them ideal for dissipating heat efficiently, thereby enhancing the performance and longevity of electronic components.

Tungsten copper alloys are composite materials made by combining tungsten, known for its high melting point and thermal conductivity, with copper, which provides excellent electrical conductivity and ductility. The resulting alloy harnesses the best qualities of both metals: it retains tungsten’s ability to withstand extreme temperatures while benefiting from copper’s superior ability to conduct electricity. This makes tungsten copper an exceptional choice for applications where efficient heat dissipation is crucial.

The effectiveness of these alloys in achieving maximum heat transfer lies in their tailored composition. By adjusting the ratio of tungsten to copper, manufacturers can engineer an alloy with specific thermal expansion coefficients that match those of semiconductor materials such as silicon or gallium arsenide. This compatibility minimizes thermal stress during temperature fluctuations, reducing the risk of damage or failure AMT in sensitive electronic components.

Moreover, tungsten copper heat sinks excel at spreading out concentrated sources of heat over a larger area due to their high thermal conductivity. This characteristic ensures that hotspots—areas within electronics where excessive heat might accumulate—are effectively managed, preventing potential overheating issues. As a result, devices equipped with these advanced heat sinks can operate at higher power levels without compromising reliability or performance.

Additionally, their robust nature allows them to function under harsh conditions often encountered in aerospace and military applications where equipment must endure significant mechanical stresses and temperature variations. Tungsten copper’s resilience ensures consistent performance even when subjected to these demanding environments.

In manufacturing processes like powder metallurgy used for producing these alloys ensure precise control over material properties such as density distribution and porosity levels; factors critical in optimizing thermal management capabilities further enhance efficiency across various implementations—from consumer electronics like laptops and smartphones all way up through industrial machinery requiring substantial cooling solutions.

In conclusion, leveraging tungsten copper heat sink alloys represents a strategic approach towards maximizing thermal management efficiency across diverse technological landscapes today increasingly characterized by miniaturization trends coupled alongside rising operational demands placed upon modern-day circuitry systems worldwide—a testament indeed showcasing how innovation continues driving forward progress within field engineering sciences aimed ultimately ensuring sustainable future advancements remain viable well into foreseeable horizons ahead!